FAQ

Frequently Asked Questions About Welding Fume Extractors

What Is a Fume Extractor?

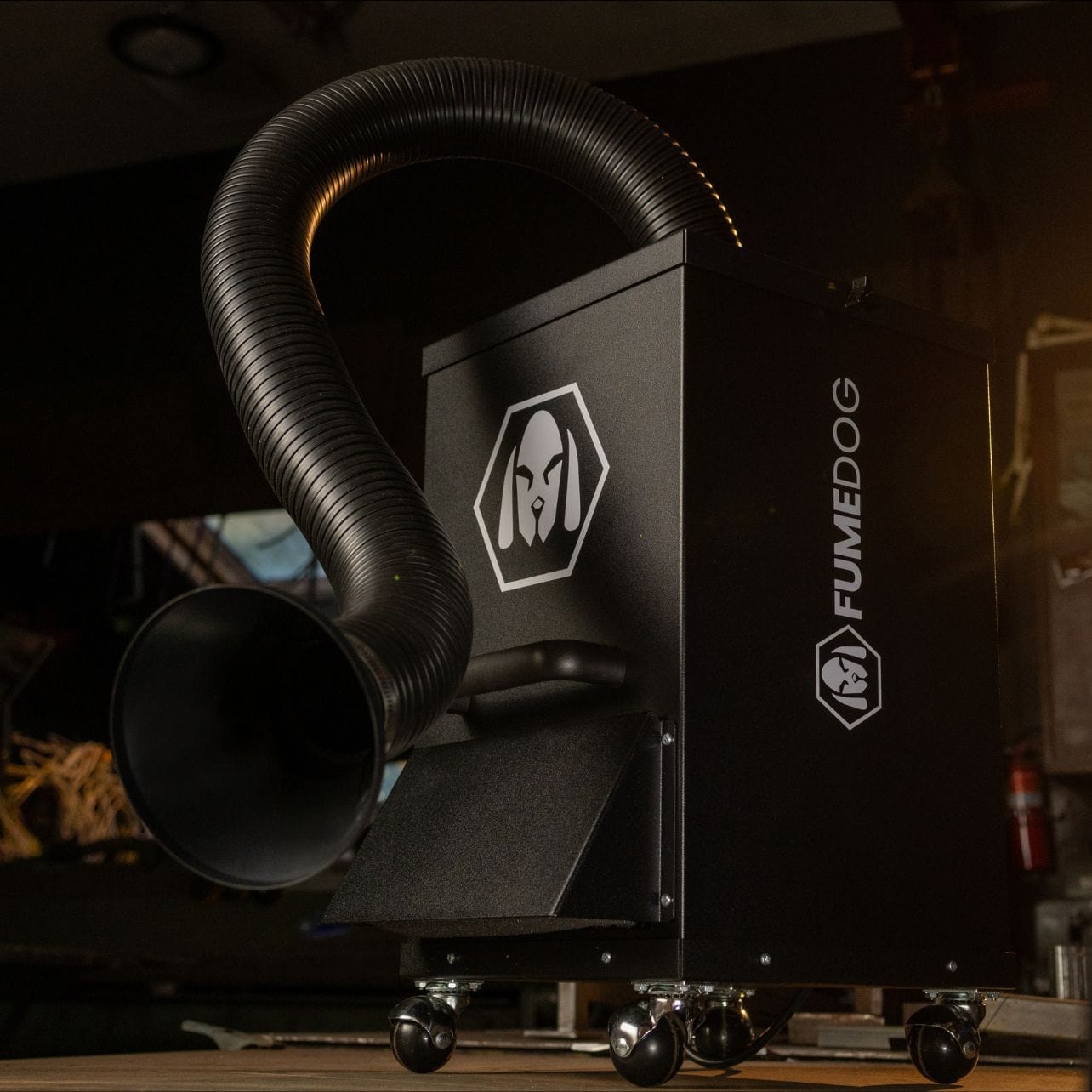

A fume extractor is at heart a simple machine used in many welding shops. Dirty air is sucked up at the fume arm (snorkel), drawn through to the filter media, and then clean air passes through the fan and out the exhaust.

Though simple in concept, the craftsmanship and knowledge required make it more difficult in execution than it would seem. Different particles (fume and dust) require different filters of varying degrees of efficiency for industrial applications and required ventilation guidelines. Getting the ideal airflow so that the fume can be extracted from while not pulling the shielding gas requires careful consideration.

At the end of the day, a weld fume extractor sucks dirty air in and exhausts clean air so you don’t inhale dangerous, cancer-causing fumes.

How Does a Portable Fume Extractor Work?

Essentially, portable fume extractors are devices that use fans to draw welding fumes and dust particles into a confined filtration system using negative airflow, allowing for improved fume control in the operator's breathing zone. This process will remove any hazardous gases and airborne particles from your environment, keeping your welding environment free from things that could negatively impact health. You will be able to move this fume extractor to any room of your choosing, allowing for a perfect solution for mobility.

What Is the Difference Between Portable Smoke Eaters and Regular Ambient Air Cleaners in the Industry?

A smoke eater is specifically made to help remove cigarette smoke, cigar smoke, cannabis smoke, or vape smoke, which makes it different from other home air purifiers.

Ambient air cleaners are useful additions to fume extractors, but they shouldn't be used as the primary way to manage harmful fumes. Due to the way ambient air cleaners work, fumes must first pass by a welder's breathing area before settling into the ambient unit's collection zone.

As a result, the welder is exposed to the same amount of hazardous welding fumes as if the extraction equipment were not there at all.

If I Have Multiple Stations, Can I Turn Off the Airflow to a Single Station?

The airflow to a certain station can be adjusted depending on which accessory arms are being used with the system. An operator can cut off the airflow to a single station using the adjustable airflow control that is included with the 2-inch metal flex arms and articulated arms.

What Is the Life of the Fume Extraction Filters?

To be specific, the answer is it depends. Wire size? How many shifts? Mild Steel? Is the steel oily? A lot of questions need to be asked to give an exact answer.

That said, you’ll generally get about a year of filter life assuming clean steel, .045 wire size, and one shift a day with an average 35% under the hood time. That is of course if you are using our cleaning system at least once a week, which allows for a longer filter life.

How Often Should I Clean My Fume Extractor Filters?

Depending on the kind of portable fume extraction systems you have, you will need to use the cleaning system and empty the dust tray on a weekly basis. The tray gathers airborne particles in addition to those from the extracted fumes. In order to prevent buildup, you need to empty the dust pan.

How Do I Choose a Fume Extractor?

1. How much are replacement filters?

- Most companies in this business want to sell you replacement filters, not a fume extractor. Prices upward of $400-$600 are common, most people don’t know to ask.

2. What is the diameter of the fume arm?

- If they say 6”, don’t believe them when they say the performance is 1,200 CFM

3. What is it made of?

- Don’t buy something made of plastic that is used around welding.