Breathing harmful fumes at work is a serious problem. Did you know contaminated air can impact your health and reduce workplace safety? This blog will explain how a fume ventilation system removes fumes and improves air quality.

Keep reading to learn which system fits your needs best!

Key Takeaways

- A fume ventilation system removes harmful fumes and particles, protecting workers' health and improving air quality.

- Key components include hoods, filters, extraction arms, ducts, fans, and control panels for efficient operation.

- Systems comply with OSHA standards to ensure workplace safety and meet industry regulations like EPA clean air guidelines.

- Portable systems offer mobility for small tasks, while fixed systems suit larger spaces with higher airflow needs.

- Regular maintenance, like filter changes and cleaning, extends the system's lifespan and ensures peak performance.

See Our Featured Products

Ensure Clean Air with the Right Fume Ventilation System

Protect your workspace from harmful fumes with a high-performance fume ventilation system from Fume Dog. Whether you're outfitting a welding booth, upgrading your filtration system, or designing a custom ventilation setup, we have the solutions to keep your air clean and your team safe.

Browse our selection of welding booth accessories and fume extraction equipment to find the perfect fit for your needs. Keep your system running efficiently with replacement filters, or explore our Welding Lab Designer to create a tailored ventilation setup.

For expert advice on selecting the right system, call 1-800-980-3481 today and let Fume Dog help you achieve a cleaner, safer work environment.

What is a Fume Ventilation System?

A fume ventilation system removes harmful fumes and particles from the air. It ensures clean air by capturing contaminants at their source.

Purpose and Importance

Fume ventilation systems protect workers by removing harmful contaminants like smoke, dust, and hazardous particles from the air. Welding processes release airborne contaminants such as soldering smoke and exhaust fumes that can harm the lungs over time.

Proper fume extraction keeps the work environment safe, reducing odors and preventing contamination.

These systems also help industries comply with OSHA standards for workplace safety. Efficient airflow ensures clean air in welding booths or other facilities where fumes accumulate.

These systems enhance health and productivity at worksites by capturing dangerous particulates with tools like activated carbon filters or a flexible hose.

Key Components and How They Work

A fume ventilation system protects workers by removing harmful fumes. Each component works together for effective extraction and filtration.

- Hood: Captures fumes directly from the source. It ensures minimal exposure to toxic particles during welding or similar tasks.

- Extraction Arm: Directs fumes into the ventilation system. It is adjustable, making it easier to position near work areas.

- Ductwork: Channels the removed fumes to filters or outside the facility. Properly installed ducts prevent leaks and ensure smooth airflow.

- Filtration Unit: Removes contaminants like dust, smoke, or gases from the air. Regular filter replacements maintain its efficiency and extend filter life.

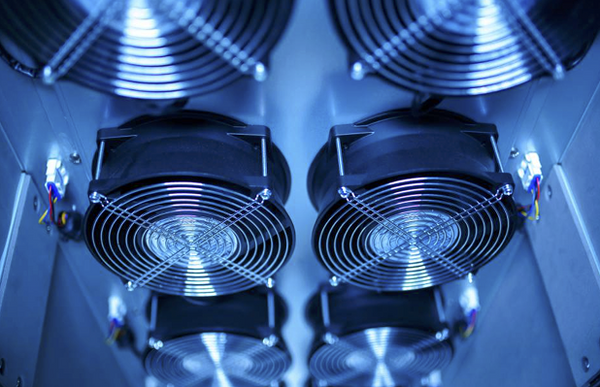

- Fan or Blower: This creates the suction needed to pull in air through the system. A strong fan ensures consistent airflow, even with heavy smoke.

- Control Panel: Allows users to adjust settings for optimal performance. Some systems have lights that signal maintenance needs or issues.

- Wall Mount Option (for wall-mounted fume extractors): Saves space in smaller facilities while providing powerful extraction capabilities.

- Portable Units (for portable fume extraction systems): Offers flexibility for welders working in different locations within a plant or shop.

- Discharge Outlet: Safely releases filtered air back into the workplace or moves it outdoors based on compliance rules.

- Filter Access Ports: Simplifies cleaning and replacing filters without disassembling other equipment parts.

Types of Fume Ventilation Systems

Fume ventilation systems come in different forms to tackle various workplace needs. Each type serves a unique purpose for removing fumes efficiently.

Local Exhaust Ventilation (LEV)

Local Exhaust Ventilation (LEV) systems remove harmful fumes directly at the source. These systems use hoods, ductwork, and filters to capture contaminants before they spread in a workspace.

Workers stay safer with LEVs by minimizing exposure to welding smoke and toxic particles. Proper installation ensures that these fume extractors work efficiently in removing fumes from the air.

Dilution Ventilation Systems

Dilution ventilation systems reduce airborne contaminants by mixing polluted air with clean air. This process lowers fume concentrations across the workspace. These systems work best for large, open areas where fumes disperse evenly rather than concentrating in one spot.

They require proper airflow to prevent the dangerous accumulation of gases. Industrial welding setups often use this method when local exhaust is less practical. The right fume extractor ensures safe breathing environments and compliance.

Next, explore Portable vs. Fixed Systems for flexibility and efficiency options!

Portable vs. Fixed Systems

Portable and fixed fume ventilation systems both work to create safer environments. Each type has specific strengths. Below is a quick comparison to help you decide which system fits your welding operation.

| Feature | Portable Systems | Fixed Systems |

|---|---|---|

| Mobility | Highly mobile and easy to relocate. | Permanently installed in one area. |

| Installation | No complex setup. Plug-and-play design. | Requires professional installation and planning. |

| Cost | Lower upfront cost compared to fixed units. | Typically, it is more expensive due to installation needs. |

| Airflow Range | Limited to smaller areas or specific tasks. | Covers larger spaces and multiple welding stations. |

| Flexibility | Great for temporary or changing tasks. | Ideal for consistent, ongoing operations. |

| Maintenance | Simple to clean but may need frequent filter changes. | It requires less frequent maintenance but is more complex. |

| Compliance | Meets basic OSHA standards for small operations. | Designed to meet stricter regulations for large facilities. |

| Noise Levels | Slightly noisier due to the compact motors. | Quieter due to more advanced systems. |

Check Our Latest Products

Choosing the Right Fume Ventilation System

Select a system that matches your workspace and airflow needs. Ensure it complies with safety standards for your industry.

Factors to Consider: Airflow, Space, and Compliance

Choosing the right fume ventilation system is crucial for safety and efficiency. Focus on key factors like airflow, available space, and compliance standards.

- Assess airflow requirements to ensure effective removal of fumes. Calculate based on the specific needs of your welding operations.

- Measure the workspace dimensions accurately before selecting a system. A compact unit might suit small areas, while larger industrial spaces may need fixed systems equipped with higher capacity.

- Evaluate industry regulations to maintain compliance. Research OSHA standards and other local rules to avoid penalties or operational shutdowns.

- Check how compatible the system is with the existing equipment in your facility. Mismatched setups can reduce performance and create hazards.

- Ensure customer service support is available for the ongoing maintenance needs of your chosen system.

- Consider noise levels if workers operate near the unit daily. Excessive noise can impact work quality and productivity over time.

- Choose a model that aligns with environmental safety guidelines to meet emission standards effectively.

- Verify product warranties before purchase to prevent unexpected costs later.

Check Our Latest Picks

Industry-Specific Requirements

Industrial welding professionals must adhere to strict ventilation guidelines. OSHA requires fume levels in workplaces to stay below established exposure limits like the permissible exposure limit (PEL).

Welding tasks involving metals such as stainless steel or aluminum demand more efficient systems due to toxic fumes from cadmium or hexavalent chromium. These materials need local exhaust ventilation (LEV) with high airflow rates and proper filtration.

Industries working in confined spaces, like shipbuilding, face challenges in meeting air quality standards. In such settings, portable systems become essential for flexibility and compliance.

Properly designed ventilation ensures adherence to health codes without risking penalties. Consider industry needs before selecting your fume ventilation system for efficiency and safety.

Benefits of Proper Fume Ventilation

Proper fume ventilation creates a safer work environment and ensures cleaner air quality. It reduces exposure to harmful gases, protecting workers from health risks.

Health and Safety Improvements

Fume ventilation systems reduce toxic airborne substances in industrial spaces. Welding fumes contain harmful particles like manganese or hexavalent chromium. These can cause serious health problems, including lung disease and metal fume fever.

Effective ventilation removes such dangers and improves indoor air quality.

Workers stay healthier and safer with fewer respiratory risks. This boosts team morale while lowering absenteeism caused by hazardous exposure. Choosing the right system also ensures compliance with workplace safety standards, protecting businesses from penalties or shutdowns.

Explore industry-specific requirements to find a suitable system for your needs next.

Compliance with Environmental Regulations

Protecting employee health also plays a role in meeting environmental regulations. Proper fume ventilation systems reduce hazardous emissions, ensuring facilities meet clean air standards set by agencies like the EPA.

Industries that ignore compliance risk penalties and operational shutdowns. Installing high-quality systems helps businesses stay within legal limits while maintaining a safer workspace for everyone involved.

Enhanced Productivity and Work Quality

A proper fume ventilation system removes harmful fumes and improves air quality. Cleaner air reduces worker fatigue, leading to better focus and fewer mistakes. This directly boosts work output in welding tasks.

Efficient systems also ensure consistent performance of tools and machinery by preventing fume buildup. This leads to higher-quality welds without disruptions or rework. Choosing the right setup depends on multiple factors discussed next.

Maintenance and Upkeep of Fume Ventilation Systems

Perform regular checks to ensure your system runs efficiently and safely.

Regular Filter Replacements and Cleaning

Filters in a fume ventilation system need attention to ensure peak performance. Regular replacements and cleaning keep the airflow smooth and safe for use.

- Change filters as recommended by the manufacturer to prevent clogs. Dirty filters reduce efficiency and compromise air quality.

- Inspect filters monthly for dust, debris, or damage. Early detection prevents costly repairs later.

- Use industrial-grade vacuuming tools to clean removable filters properly. This step removes fine particles that block airflow.

- Dispose of damaged or heavily clogged filters immediately to maintain system safety.

- Clean ducts and filter housing at least once every six months. Contaminants can build up even in hard-to-reach spaces.

- Schedule professional inspections annually for deeper maintenance tasks. Certified technicians detect issues professionals may miss during routine checks.

- Document all filter changes and cleanings to effectively track usage over time. This record helps identify patterns of wear or failure early on.

Maintaining your fume ventilation is essential for health, compliance, and productivity!

Common Troubleshooting Tips

Troubleshooting a fume ventilation system can save time and money. Regular checks ensure safety and efficiency in industrial welding environments.

- Check airflow consistency. Reduced airflow could mean blockages in ducts or filters.

- Inspect the motor for unusual noises. Grinding or humming might indicate worn-out parts.

- Look for visible wear on belts and fans. Damaged components impact system performance.

- Clean clogged filters immediately. Dusty filters restrict proper ventilation.

- Confirm that dampers open and close smoothly. Stuck dampers affect air movement.

- Ensure control systems respond correctly to adjustments. Faulty controls disrupt operations.

- Examine ducts for leaks or damage. Cracks reduce suction power and waste energy.

- Test air quality around vents frequently. Poor readings suggest malfunctioning parts.

- Verify compliance with industry standards regularly. Non-compliance risks safety fines and delays.

- Contact qualified technicians if problems persist after basic steps fail.

Conclusion

A good fume ventilation system keeps your workplace safe and efficient. It protects workers from harmful fumes and ensures clean air. Proper maintenance makes it last longer and works better.

Invest in the right system to boost safety and productivity. Healthy air means a healthier team!

FAQs

1. What is a fume ventilation system?

A fume ventilation system removes harmful fumes, smoke, and gases from the air to keep space safe and clean.

2. Why is a fume ventilation system important?

It protects people by improving air quality and reducing exposure to dangerous chemicals or particles.

3. Where are fume ventilation systems used?

They are often used in labs, factories, workshops, and other places where toxic fumes may form.

4. How do you maintain a fume ventilation system?

Regularly check filters, clean ducts, inspect fans, and ensure all parts work properly for safety and efficiency.